HZ-S0206

Cov qauv tsis muaj

Basic tsis

| Qauv | HZ-S0206 |

|

Xim kub / xim | 2300k ua |

| 2700k ua | |

| 3000 K | |

| 4000 K | |

| 6000k ib | |

| Sib piv lub teeb sawb | 2216-240-24V-3 hli |

| CRI | ~ 90 |

| Qhov voltage (V) | 24 |

| Hluav taws xob tam sim no (A) | 0.48 ib |

| Lub zog (W / m) | 5 |

| lm / wavelength | 107 |

| 108 | |

| 113 | |

| 126 | |

| 130 | |

| Loj (mm) | 2.5 × 6 |

| Txheem ntev | 5000 hli |

| Shear unit (mm) | 25 |

| Kev ntsuas IP | IP67 |

Txoj kev txuas

Mechanical Parameters

Cov nplaum nplaum

Cov txheej txheem ntau lawm

Raw Material Procurement

1.Chip xaiv: Raws li kev ua tau zoo ntawm qhov ci, xim kub, xim rendering Performance index thiab lwm yam khoom hauv cov khoom tsim, zoo SMD LED chips yog yuav los ntawm cov neeg muag khoom txhim khu kev qha. Cov chips no yuav tsum tau soj ntsuam nruj me ntsis ua ntej kev yuav khoom los xyuas kom meej tias cov khoom siv hluav taws xob thiab kho qhov muag ua tau raws li cov qauv.

2.Circuit Board Procurement: Xaiv lub rooj tsav xwm zoo FPCB, ntsuas nws qhov kub thiab txias, conductivity thiab saj zawg zog, thiab yuav ntau yam khoom siv hluav taws xob uas xav tau rau kev tsim khoom tib lub sijhawm, xws li capacitors thiab resistors, txhua yam yuav tsum tau ua raws li cov qauv tsim.

3.Auxiliary Material Procurement: Yuav cov ntaub ntawv pabcuam xws li 3M nplaum rau kev sib dhos strip, solder paste rau vuam thiab kua nplaum rau encapsulation thiab kev tiv thaiv, thiab xyuas kom meej tias lawv cov viscosity, stability thiab lwm yam ntxwv phim cov txheej txheem ntau lawm.

Patch txheej txheem

1.Solder Paste Printing: Cov tshuaj nplaum nplaum yog raug coated rau ntawm qhov chaw ntawm FPCB Circuit Board. Siv lub tshuab luam ntawv high-precision solder paste thiab raws li lub preset template, lub thickness thiab cov duab ntawm solder paste yog guaranteed kom zoo ib yam thiab muaj tseeb, nteg lub hauv paus zoo rau cov hlaws tom ntej.

2.Bead Patching: Nrog kev pab los ntawm lub tshuab muab tso rau hauv lub tshuab tsis siv neeg, cov khoom siv SMD LED hlaws tau nrawm thiab raug txuas nrog cov ntaub ntawv luam tawm nrog cov nplaum nplaum raws li tus qauv tsim. Cov txheej txheem patching yog saib xyuas los ntawm lub tshuab tsis pom kev thoob plaws hauv cov txheej txheem, thiab kev sib txawv me ntsis tuaj yeem raug kho raws sijhawm.

Kev tshuaj xyuas qhov muag

Ua phau ntawv pom kev tshuaj xyuas ntawm qhov chaw-mounted LED sawb.

Reflow Soldering

1.Parameter Chaw: Raws li cov yam ntxwv ntawm cov khoom siv thiab cov kev qhia tshwj xeeb ntawm cov hlaws dai, ua tib zoo kho qhov tsis sib xws ntawm txhua qhov kub thiab txias ntawm lub tshuab reflow soldering, suav nrog qhov kub thiab txias, qhov ntsuas kub, qhov kub thiab txias. Qhov tseeb parameter teeb yog tus yuam sij rau vuam zoo.

2.Welding Execution: Muab lub patched Circuit Board rau ntawm txoj siv conveyor ntawm lub tshuab reflow soldering. Raws li lub rooj tsav xwm Circuit Court dhau los ntawm qhov preheating, reflow thiab txias qhov chaw nyob rau hauv lem, lub solder paste yog rhuab kom yaj thiab solidify, realizing lub ruaj hluav taws xob kev twb kev txuas ntawm cov hlaws dai thiab Circuit Court board. Thaum lub sij hawm no, tus neeg teb xov tooj them nyiaj mloog zoo rau kev khiav haujlwm ntawm cov khoom siv.

Kev tshuaj xyuas thiab kho

1. Kev tshuaj xyuas qhov muag: Ua ib qho kev soj ntsuam ua ntej ntawm cov welded sawb los xyuas seb puas muaj cov khoom siv hluav taws xob, tsis muaj kev sib txuas, tsis tu ncua ntawm cov hlaws dai, seb cov hlaws puas puas lossis raug tshem tawm, thiab seb puas muaj qhov khawb lossis lwm yam tsis xws luag ntawm lub rooj tsavxwm Circuit Court. .

2.Power-on Test: Txuas lub sawb mus rau qhov tsim nyog 24V fais fab mov, saib xyuas lub teeb pom kev zoo ntawm cov hlaws dai, xyuas seb lub teeb pom kev zoo li cas, seb puas muaj lub teeb stroboscopic thiab seb cov xim kub zoo li cas. Kos cov khoom tsis raug thiab npaj cov neeg ua haujlwm tu neeg ua haujlwm los kho lawv.

Neon Extrusion

1. Cov khoom sib xyaw thiab kev ua haujlwm: Ntxiv cov khoom siv silicone raw khoom thiab cov khoom siv ntxiv xws li vulcanizing cov neeg ua haujlwm rau lub tov khoom hauv ib qho kev faib ua feem thiab do thiab tig kom txog thaum cov khoom silicone yog tag nrho cov uniform. Rau qee qhov tshwj xeeb uas yuav tsum tau ua ntawm lub teeb strips, nws yuav tsum tau ntxiv cov xim masterbatch thiab lwm yam ntaub ntawv los kho cov xim.

2.FPCB Flexible Board Processing:Lub FPCB hloov tau lub rooj tsavxwm nrog ntsia LED hlaws thiab ua tiav reflow soldering yog raug rau kev laus poob siab kho mob los ntsuam xyuas nws stability thiab kev ntseeg tau. Tom qab kev poob siab ntawm kev laus, tag nrho FPCB hloov tau lub rooj tsavxwm tau muab tso rau ntawm lub rooj zaum ua haujlwm uas muaj cov tawv tawv tiv thaiv zoo li qub rau kev sib cais ntawm pawg thawj coj saib thiab muab faib ua ib leeg FPC hloov tau. Thiab qhov ci ntsa iab ntawm txhua cov hlaws LED raug sim, thiab cov neeg tsim nyog tau coiled.

3. Extrusion: Faib cov khoom sib tov thiab cov khoom silicone raws li qhov yuav tsum tau ua, tom qab ntawd xa cov FPC hloov pauv mus rau hauv lub extruder nruab nrog lub extrusion tuag, thiab xa cov khoom sib faib khoom silicone. Nyob rau tib lub sijhawm, tig rau lub qhov cub ci thiab lub extruder thiab pib extrusion thiab ci curing. Thaum lub sij hawm extrusion txheej txheem, cov yas silicone yaj txav mus rau pem hauv ntej nyob rau hauv kev sib hloov ntawm cov ntsia hlau thiab dhau los ntawm kev tuag ntawm lub extruder. Cov ntsia hlau thiab tuag ntawm lub extruder exert siab rau cov yaj kom extrude nws mus rau hauv lub tes tsho los yog lub plhaub ntawm lub neon lub teeb sawb raws li cov duab thiab loj ntawm cov tuag thiab qhwv lub FPC saj zawg zog board nyob rau hauv nws.

Txias thiab ua kom zoo

1. Cua txias: Lub extruded neon lub teeb sawb tam sim ntawd nkag mus rau hauv lub tshuab cua txias, xws li lub tank dej txias los yog lub tshuab cua txias, kom cov silicone sai sai txias thiab solidifies thiab tswj cov duab thiab loj thaum lub sij hawm extrusion.

2. Shaping:Lub neon lub teeb sawb tom qab txias muaj qee qhov hardness thiab cov duab ruaj khov thiab tuaj yeem ua tiav thiab kho tom qab.

Kev ua tom ntej

1. Txiav thiab Trimming: Txiav thiab luas lub extruded neon lub teeb sawb raws li qhov yuav tsum tau ntev. Feem ntau, cov cuab yeej txiav lossis cov cuab yeej txiav yuav raug siv los txiav lub teeb sawb mus rau hauv tus qauv ntev.

2.Kev soj ntsuam thiab kuaj: Ua qhov kev soj ntsuam xyuas, kev ntsuas hluav taws xob, thiab lwm yam ntawm lub teeb neon nrog cov hlaws teeb teeb pom kev zoo los xyuas seb lub teeb pom kev zoo li cas, xim uniformity, hluav taws xob ua haujlwm, thiab lwm yam.

Kev sib dhos thiab ntim khoom

1.Kev sib dhos ntawm Accessories: Muab tshuaj txhuam 3M nplaum rau ntawm qhov kev ntsuam xyuas tsim nyog sawb los pab txhawb kev txhim kho tom ntej. Rau cov ntaub thaiv dej tsis zoo, kev kho cov sealing ntxiv yuav raug ua, thiab lub tes tsho tsis muaj dej, roj hmab gaskets thiab lwm yam khoom yuav raug ntxiv.

2.Packaging thiab Warehouse: Cua thiab ntim cov strips nyob rau hauv ib qho kev txiav txim raws li tus qauv ntev, xws li 5000mm ib yob, muab tso rau hauv yas zaj duab xis thiab lub thawv ntim, muab cov khoom ntim, qhia cov specifications, qauv, hnub tsim khoom thiab lwm yam ntaub ntawv, thiab ces txav mus. lawv mus rau lub warehouse rau cia, tos rau cov khoom xa tuaj.

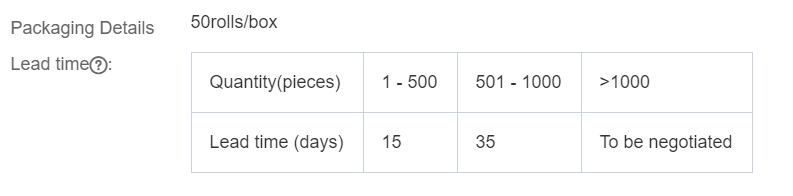

Ntim & xa khoom

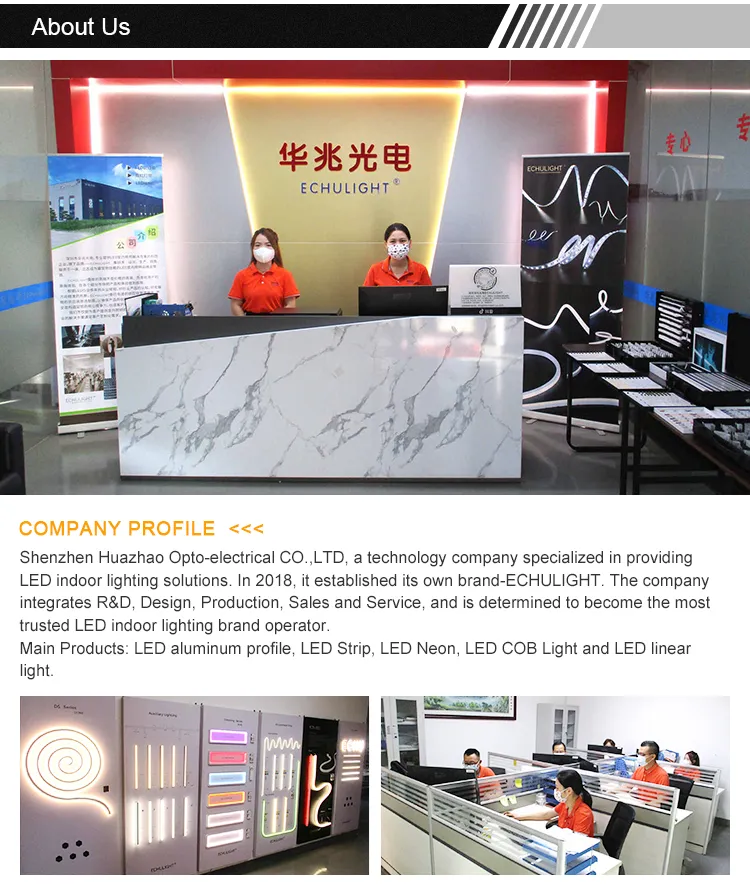

Txog Peb

Peb lub Hoobkas

Peb Qhov Zoo

Daim ntawv pov thawj

Shipping & Them Nyiaj

FAQ

Hais txogPRODUCTS

-

Xov tooj

-

E-mail

-

Sab saum toj